How to make garden furniture with your own hands, examples of drawings and photos of successful homemade products

Going to a suburban area, we want to return rested and in a good mood. In order to have a pleasant time at the cottage, it is necessary to furnish it with comfortable furniture in advance. To do this, it is recommended to make garden furniture with your own hands, successful examples of which can be seen in the photo, and the drawings will help you realize them.

Necessary materials and tools

To harmoniously fit garden furniture into the surrounding design, it is recommended to give preference to wood. Unique products come out of branches, twigs, logs and trunks. However, not only this material is suitable for self-manufacturing. Choosing the basics, you can show your imagination by trying to create unusual solutions for the site. When choosing raw materials for work, consider not only the general style, but also practicality. It is necessary to highlight several popular materials for decorating a personal plot with furniture of our own production:

- Concrete blocks - from them you can make a reliable table, which is then easily lined with patterned tiles;

- Flexible tree branches - this material makes attractive chairs, rocking chairs and tables. They are comfortable to relax in the summer heat under a canopy;

- Metal bases - metal will provide high strength, which can not be said about wood. It is difficult to work with such raw materials, it must be connected with bolts and anchors. For work, pipes made of steel or duralumin are used;

- At-hand materials - home-made furniture at no extra cost is easily made from the remnants of raw materials after repair, as well as unnecessary things. This includes pallets, tires, wooden reels from the cable.

The choice of material will depend on the preferences of the owners: if you want to create original furniture, you should give preference to non-standard solutions. If the main indicator is strength - choose metal. Of the tools, a jigsaw, drill, screwdriver, tape measure, simple pencil, hammer, drill, screwdriver will definitely come in handy. To work with wood you need a planer, a chisel, an ax. To work with metal, you will need a grinder with cutting discs. When all the necessary tools and materials are selected, you can begin to create masterpieces.

Instruments

Instruments Materials

Materials Materials

MaterialsStep-by-step instruction

The advantages of DIY garden furniture are its low cost, originality and changeability. If the furniture gets bored over time, it is easy to replace it with new products created with your own hands. Among the popular models for the garden, one can distinguish the following types of furniture:

- Bench;

- Deck chair;

- Sol;

- Furniture from pallets;

- Wicker options.

To better understand how to craft any of these items, you should consider step-by-step assembly instructions. In the course of describing the manufacture of garden furniture with your own hands, successful homemade products, photos and drawings will be presented below.

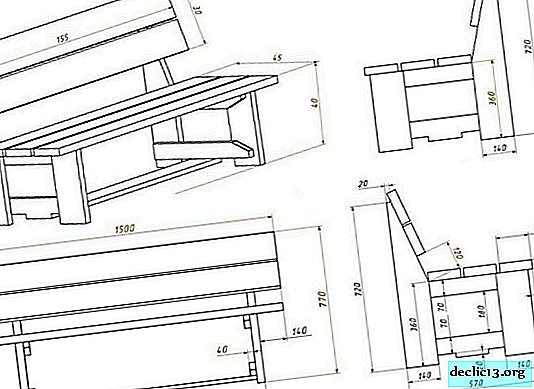

Bench

The easiest way to make a garden bench is to use wooden log cabins. Products from this material add special comfort to the summer cottage, adding natural textures and colors. You can position the bench anywhere on the site: on the porch, in the gazebo, under the trees, near bushes and even near a pond.

For independent production you will need 2 logs, one of which should be thicker than the other. Woodworking tools and thick bars are also needed. It is worth noting that the part used for the seat must be smooth. This is achieved using a milling machine. If it is not possible to use the machine - purchase a pre-logged log.

Before you start creating a bench for a summer cottage, you should decide on its type. The bench may have a backrest, be round, made of solid logs or have fixed seats.

This material proposes to make a garden bench with a back. To do this, follow the algorithm of actions:

- Saw a thick log into the logs and set them in the chosen place. The distance between them should not exceed 90 cm;

- The length of the blocks should be longer than the seat of the future bench. To do this, leave a gap of 20 cm;

- On the logs, cut out the recesses for inserting the seat. To do this, it is worth measuring the diameter of a thin log and making appropriate cuts;

- A thin log is sawed lengthwise into 2 long halves. One of them is mounted on the block, flat side up. It will be a seat;

- The bars are attached to the base of the log blocks - their length will be the height of the back;

- The second part of a thin log is attached to the bars, forming the back.

At the end of the work, all the details of the bench are opened with a protective varnish in several layers. To create a decor, you can draw a picture on the seat yourself or involve children in such a fun activity.

We process boards

We process boards We make a marking for grinding

We make a marking for grinding

We connect all the elements. The bench is ready

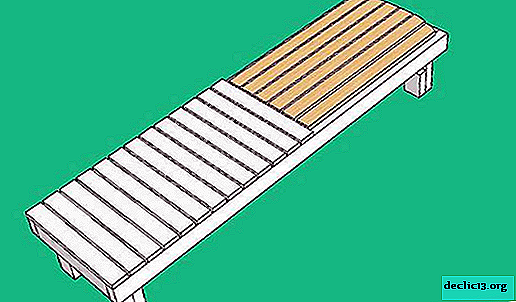

We connect all the elements. The bench is readyDeck chair

You can make a simple sunbed for relaxing in the sun from wooden bars. Furniture for the garden, made by yourself, should not be expensive, and the bars have an affordable price. The following materials will be used in the work:

| The size | amount | Destination |

| 5x10 board - 88 cm | 2 pcs | For the back |

| 5x10 board - 39 cm | 3 pcs | |

| 5x10 board - 60 cm | 1 PC | |

| Longitudinal beam 215 cm | 2 pcs | For frame |

| Cross beam 50 cm | 2 pcs | |

| 35 cm legs | 6 pcs | For legs |

| Reiki 2.5x8x60 cm | 13 pc | For sitting |

| Reiki 2.5x8x88 cm | 6 pcs | For the back |

The first thing to do is to create a solid and reliable foundation for the deck chair. To do this, use the frame parts and connect them into a rectangle with the help of screws. Next, the seat for the deck chair is made. 60 cm slats are mounted along the frame, leaving gaps of several centimeters. For uniformity of cracks use gaskets of the appropriate size.

The height of the legs for the product can be any, the specified size of 35 cm is considered optimal. The legs are screwed with screws. At the side where the legs will be, they put 2 legs at once, at the head they fasten 1 leg. Next, a frame for the back is made, it is carefully inserted into the base case, but at the same time a small gap should remain. Backrest rails are packed on the frame, they can be rounded for attractiveness. The backrest is screwed to the seat so that it can be adjusted. To do this, it is necessary to deviate from the edge of about 9 cm. Appearance is important for garden furniture, so it is better to paint the deck chair in a bright color and fix it with acrylic varnish.

Assembling the frame

Assembling the frame Make a seat

Make a seat Create a back

Create a back Sew the frame

Sew the frame Fasten the back

Fasten the back Create notches

Create notches Ready chaise lounge

Ready chaise loungeTable

Metal furniture is distinguished by its simplicity, but at the same time reliability. In the manufacture of a garden table, you can use a metal profile, which will serve as a frame. It is more profitable to make a countertop from wood or purchase a finished sheet of chipboard. To work on metal, you will need a welding machine, a grinder, a saw, as well as a special paint to prevent corrosion, brushes and a roller. In addition, you will need wood paint for processing countertops and fixing acrylic varnish.

Of the elements for the frame, profile pipes of the following sizes are required:

- 18x730 mm - 3 pcs;

- 18x385 mm - 3 pcs;

- Corners 30x30 mm, length 400 mm - 3 pcs.

The countertop should have a diameter of up to 1 meter, while its thickness should be 19 mm. You will also need screws, glue and balls for legs. The manufacturing process looks like this:

- From the corners a triangle is made with angles of 60 degrees;

- From the 38.5 cm profile, the same equilateral triangle is made;

- Using a drill and drill for metal, holes are made in the frame, where it will be mounted with a countertop;

- 73 cm pipes are bent to 65 cm with a vise and hammer. These will be the legs, a stand in the shape of a triangle is welded to them;

- The tops of bent pipes, which became the legs for the table, are welded to a triangular frame for the countertop;

- Metal balls are welded to the ends of the legs.

At the very end, the worktop is processed. If it is a chipboard, it must be carefully sanded, painted and varnished. Then attach to the table frame. There are several tabletop decor options, one of which is a stencil, considered the simplest. To do this, a drawing is printed, applied to the base, circled in pencil. The resulting image is painted in contrasting color. For a summer cottage, pictures of fruits and vegetables will become appropriate.

We connect the boards of the future countertops

We connect the boards of the future countertops Making the sidewalls

Making the sidewalls Putting the countertop and side parts together

Putting the countertop and side parts together We make legs and jumpers, we fasten them

We make legs and jumpers, we fasten them We cover the countertop with varnish

We cover the countertop with varnish The table is ready

The table is readyFrom pallets

The least expensive and most original way to make garden furniture is to use pallets. Such material does not require a specific assembly scheme, it all depends on the imagination and preferences of the owner.

Pallets can remain after transportation of building materials, they can also be found in large numbers near building supermarkets. Pallets are on sale at a low price.

The easiest way to use pallets is to make a table. To do this, it is necessary to paint the pallet in any color, open it with varnish and put on top a solid plate of chipboard, plastic or glass. You can decorate the table to your liking. The corner resting place for giving from pallets will look beautiful and practical. It is advantageous to place it in a cozy corner of the garden under the trees or near the pond. For manufacturing you will need:

- 8 pallets for seating and 6 pallets for decorating the back;

- Pallets for forming the base under the corner;

- 2 small pallets for a table;

- Fasteners and screwdriver;

- Paint, brushes, varnish.

First you need to prepare a place to install the corner. For this, solid pallets are taken, on top of which solid bases are filled. They will serve as the basis for the even arrangement of the sofa corner. Then 8 pallets for seating and 6 pieces for the back are sanded, painted and varnished. They are placed with the letter G on a previously prepared surface. From the back side to the pallets beat backs. To design a table, 2 small pallets are used, fastened together.

To save the corner from the features of the industrial style, soft pillows and rugs are placed on the surface of the new sofa. It is desirable that the color of the furniture and bedspreads be contrasting. It is convenient to place glasses with drinks, food and decor items on the table. An interesting process of making garden furniture with your own hands and successful home-made products that result as a result motivate the owners to new masterpieces. Pallets are a universal material that is useful for the manufacture of furniture, both in general and in disassembled form.

Create holes

Create holes Eliminate deformations

Eliminate deformations We clear a covering

We clear a covering Create additional holes

Create additional holes Fasten all the elements

Fasten all the elements Grind and paint the surface

Grind and paint the surface We mount the legs

We mount the legsWicker furniture

Fashion for natural materials is only increasing every year. This also applies to wicker furniture for the garden, which brings a feeling of comfort to the cottage. Such furniture can be classified as “do it yourself”, because even the children will like the weaving process.

Raw materials for natural wicker furniture today are:

- Banana leaves;

- Hyacinth;

- Bamboo;

- Seaweed;

- Rattan;

- Willow.

For beginners, working with bending branches of bird cherry is best suited. It is easy to process, because it has increased ductility. For weaving use rods that do not contain kidneys. They are cut at an angle of 40 degrees and tested for flexibility. To improve the characteristics of the rods, they boil in water for about an hour, dark branches are boiled for 3 hours. For the production of a small sofa, a frame of 4 rods is made. At the next stage, the seat is braided, after which the legs are created.

A long stick is screwed to the legs, with which the back braiding begins. After manufacturing, it is desirable to additionally wrap the entire structure with willow vine - it is thinner. A plywood sheet is laid on the seat and decorated. The final stage of work is the covering of the sofa with a stain to prevent damage to furniture. You can put a bright mattress on top or fill the seat with small pillows. If there is no experience in weaving furniture, first it is better to practice the manufacture of baskets. So you can fully feel the vine. Do-it-yourself garden furniture is always original and individual. If you want to surprise your friends and acquaintances - try to make a table or bench yourself.

Frame manufacturing diagram

Frame manufacturing diagram We mount the frame

We mount the frame Lubricate the frame with glue

Lubricate the frame with glue Choose the type of weaving and start work

Choose the type of weaving and start work