Overview of MDF furniture, properties and operational characteristics of the material

Such items are made from completely different materials. The appearance of any structure, its resistance to moisture or mechanical shock, cost and other parameters depends on the raw materials used. Therefore, many people when choosing furniture take into account the material of its manufacture. Furniture from MDF is considered to be quite in demand, it is presented in numerous models. Plates are used to create cabinets, walls, cabinets, kitchen sets and other furnishings.

Features and dimensions of MDF

MDF, which is used in the manufacture of furniture, is created from sawdust, which are pre-pressed well, and then glued using a special substance - lignin. All components are environmentally friendly, therefore, products from the plates are safe for use in the children's room.

Due to the specific production process, a material is obtained that has good strength and other advantages:

- From it you can make high quality furniture;

- The structure of the material is homogeneous, it does not have any protruding fractions;

- Environmental friendliness and safety for the human body;

- Good moisture resistance, allowing the use of stoves in the kitchen or in the bathroom;

- Resistance to deformation;

- A wide palette of shades allows you to choose elements of a suitable color or texture.

The disadvantages include the fact that furniture made of veneered MDF has a higher cost compared to structures made of chipboard or plastic. If you act on it with significant mechanical loads, then cracks or dents may appear. Also, MDF is a highly flammable material, therefore it is not allowed to use it to create products that will be located next to an open flame.

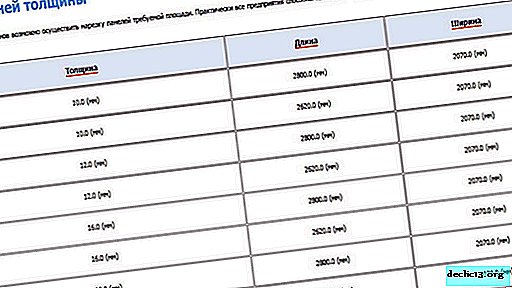

Sheet sizes are standardly equal:

- If the thickness varies from 3 to 14 mm, then the area of the plates will be 2070x2800 mm or 2070x2620 mm;

- With a thickness ranging from 16 to 24 mm, the sheet has a size of 2070x2800 mm;

- The thickest plates, reaching a thickness of 38 mm, have a size of 2700x2800 mm.

The most popular are MDF panels 2070x2800 mm. When creating complicated moisture-resistant sheets, it is possible to produce mainly sheets of 1220x2440 mm.

Forms and methods of processing material

What is MDF in furniture? The interpretation of this designation is a finely divided fraction obtained from small wastes of the woodworking industry. The production procedure involves the formation of a special mass of chips and glue. From it, plates of different thicknesses, areas and shapes are formed. If necessary, the desired relief can be made, which is especially important for creating unique furniture equipped with bent and elegant facades.

Panels, countertops, plinths, platbands or other products necessary not only for creating furniture, but also for decorating a room are made of this material. Particularly in demand are considered MDF furniture profiles that complete any decoration.

Furniture MDF panels have a fine-fiber structure, therefore, when they are processed or milled, a lot of dust is generated. Due to the ease of cutting, you can independently create unique carved structures. Simplicity of processing allows using panels to create cabinet, built-in or modular furniture. When using CNC machines, you can even make curly images.

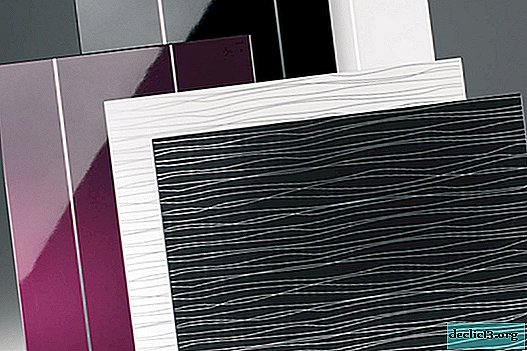

To improve the appearance and quality of furniture, different processing or decoration methods are used.

| Processing method | Its features |

| Lamination | From the outside, the panel is covered with a special PVC film, which is glued under high pressure. Due to this treatment, a matte or glossy surface is obtained. It can imitate various expensive materials, as well as be made in a variety of shades. The resulting coating is durable, resistant to sunlight and chemicals, high hygiene and easy to care for. |

| Veneering | The veneer can adhere to one or two sides of the board. To create it, valuable species of wood are used, therefore, outwardly expensive furniture is obtained. When using veneer, the price of structures increases significantly. Due to this treatment, moisture-resistant panels are obtained that are resistant to warping and drying. |

| For painting | Such panels are fully extruded and have an unpainted surface. In this case, customers can decide for themselves what color and quality paint suits them best. Painting is carried out manually or using a special tool. |

There are many decors for such panels, which are selected by the users themselves.

Laminated

Laminated Veneered

Veneered For painting

For paintingThe main varieties of MDF products include:

- Decorative panels for walls - equipped with grooves and ridges, simplifying installation. Wall coatings are formed from them in different rooms. To fix the elements, you can use glue or create a frame. They are distinguished by ease of installation, beautiful views, good thermal insulation and sound insulation. But such decorative elements are easily destroyed by mechanical action, easily ignite and have a high price;

- Moisture-proof panels - are considered universal products that are highly resistant to moisture. They are considered ideal for a bathroom or kitchen. Moreover, they are easy to process, durable and have good soundproofing parameters;

- Glossy canvases - these MDF furniture panels are most often used to create kitchen sets, cabinets or hallways. Due to the glossy finish they are distinguished by their exquisite appearance, and also fit well into different interior styles. Additionally, this coating is well protected from various mechanical influences. Guaranteed long life. To create a coating, polyester or primer can be used;

- Flexible panels - appeared on the market relatively recently, but quickly became popular. They can take any form, therefore they are effectively used to create bent facades, arches and other structures. Flexible elements have smooth surfaces that can be painted or decorated in different ways. With the help of such a painted curved facade, you can improve the appearance of any room.

The thickness of the MDF can vary from 4 to 16 mm. The lower this indicator, the more simple the plates will be in processing. But the subtle elements are quite fragile.

Flexible

Flexible For walls

For walls Moisture resistant

Moisture resistant Glossy

GlossyTypes of furniture

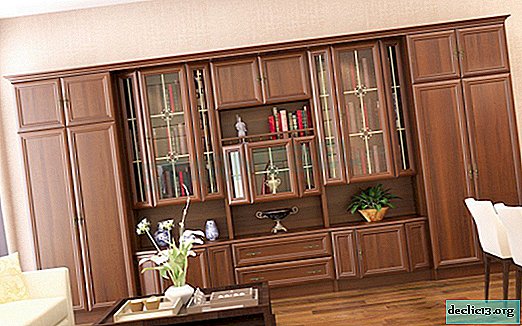

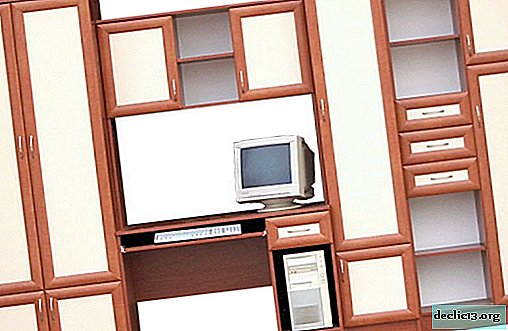

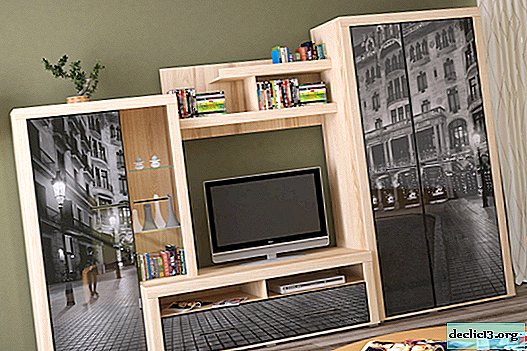

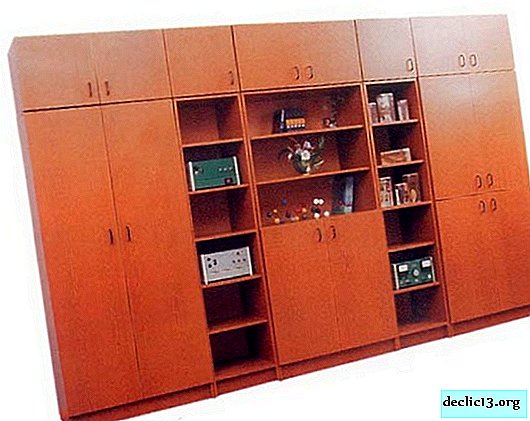

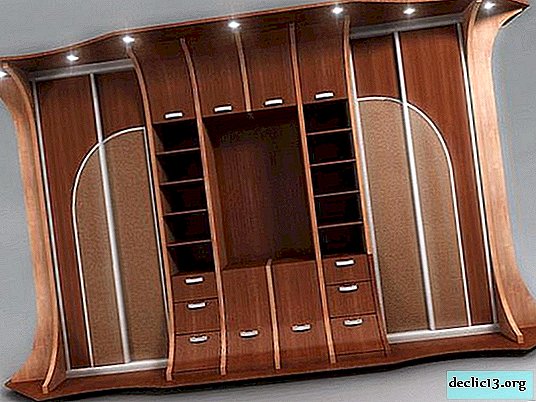

Photos of furniture from MDF can be viewed below. The material is universal, so different interior items can be made from it. They differ in operating conditions, sizes, shapes or other properties. For each room, it is advisable to select designs taking into account the peculiarities of the situation.

The main types of furniture made of this material include products:

- For the kitchen - in this room, facades for a kitchen set from MDF are usually used. The body of such a product is made of chipboard or other similar material, but the external elements are made of MDF. Facades can be decorated with different films, milling, glasses, mirrors or other elements. The material perfectly withstands exposure to high temperature and humidity;

- For the children's room - the composition of the material does not contain harmful substances, therefore, MDF structures can be created even for children. Usually different lockers, changing tables, bedside tables and dressers are made. All edges are milled to remove sharp corners that babies might hurt;

- For the bathroom - the material can easily withstand high humidity, so it is often found in the bathroom. Due to the ease of processing, you can get custom designs that fit well into small or unusual-shaped rooms. Furniture is presented by cabinets, bedside tables, coasters, small ladders for children or drawers;

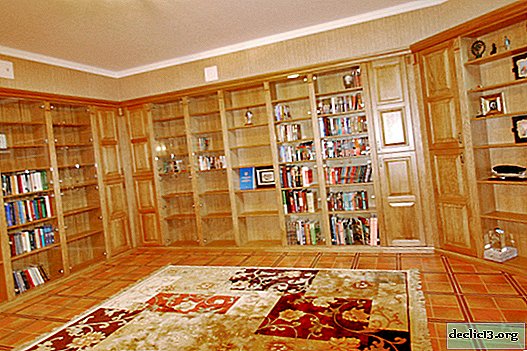

- For the living room. MDF is often used to form walls, cabinets, cabinets, tables or other products installed in halls;

- For public buildings - often MDF makes furniture for libraries, offices, schools, kindergartens or other institutions. It has an interesting appearance, a long service life and resistance to shock and pollution. Such designs are presented by tables, cabinets, cabinets and other products.

Thus, MDF is used in the creation of various furnishings, and they can be installed not only in apartments or houses, but also in different public areas.

Living room

Living room Library

Library Bathroom

Bathroom Kitchen

Kitchen Children

ChildrenSafe use and care

It is important not only to correctly select designs, but also to figure out how to properly care for furniture from MDF, so that it always remains attractive and lasts a long time.

Basic care rules:

- For cleaning, you can not use aggressive chemicals that damage decorative surfaces;

- Means are selected that contain no alkalis, acids or oxidizing components;

- It is forbidden to use detergents intended for solid wood furniture, since their use can cause the appearance of bloating or a change in the color of the MDF product;

- Steam cleaning is not permitted;

- Hard washcloths provoke scratches;

- To care for furniture from MDF, it is recommended to buy special products designed for these purposes;

- Dry and clean rags are excellent for dust removal;

- Surface treatment can be carried out by antistatic agents;

- If severe impurities are found, then they are eliminated with a mild soap solution;

- It is allowed to use ethanol, but it must be removed from the surface promptly, otherwise it can harm the surface of MDF;

- After cleaning, all coatings are wiped dry.

Furniture made of MDF is presented in different models, which differ in shapes, dimensions, colors and other characteristics. It can be selected for different rooms and is often used in public places. This is a great alternative to solid wood products - furniture looks modern and expensive. To increase the service life, it is necessary to provide products with high-quality and proper care.

Photo